GS1 Terminology

IDENTIFY

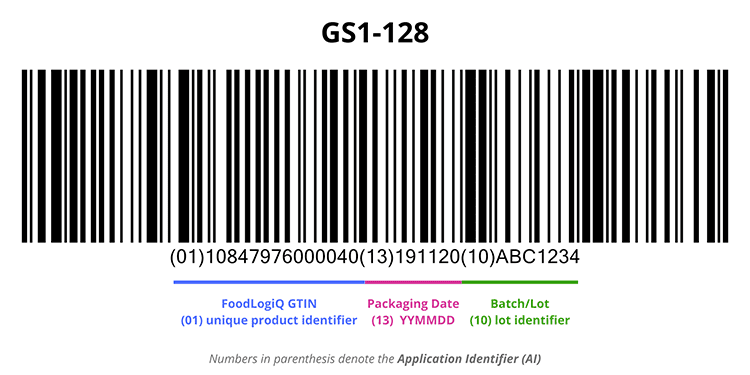

GS1 utilizes globally unique identifiers for products and locations. These can then be used across any supply chain to look up product information in a database, or be encoded into a data carrier and then capture information through scanning the barcode.

GS1 Company Prefix: the GS1 Company prefix is a unique identifier for your company assigned by GS1, used globally. Learn how to get your GS1 prefix using the GS1 US’s starters guide.

GTIN®: the Global Trade Item Number (GTIN) is a 14 digit identifier for products or services exchanged in the supply chain. For products, companies will assign a Global Trade Item Number (GTIN). These are comprised of four components: 1) Indicator Digit, 2) Your GS1 Company Prefix, 3) Item Reference Number, 4) Check Digit.

GTIN Example: 10847976000040

- 1 = Indicator Digit

- 0847976 = FoodLogiQ GS1 Company Prefix

- 00004 = Item Reference Number

- 0 = Check Digit

The Check Digit is calculated and there are several tools to create them. GTIN is an attribute in Trustwell’s FoodLogiQ platform, and the system can automatically generate the check digit, per the GS1 Standard. Read the GS1 US resource on GTIN assignment and use.

GLN: the Global Location Number (GLN) is a 13 digit identifier for locations, both physical or digital, which can be as specific as a location within a store or an instance in a database. GLNs can also be descriptive of legal entities. For products, companies will assign a Global Trade Item Number (GTIN). These are comprised of three components: 1) Your GS1 Company Prefix, 2) Item Reference Number, 3) Check Digit.

GLN Example: 0847976000005

- 0847976 = FoodLogiQ GS1 Company Prefix

- 00000 = Location Reference Number

- 5 = Check Digit

The Check Digit is calculated and there are several tools to create them. GLN is an attribute in Trustwell’s FoodLogiQ platform, and the system can automatically generate the check digit, per the GS1 Standard. Read the GS1 US resource on how to use a GLN to maximize supply chain visibility and traceability for more information.

SSCC: Serial Shipping Container Codes (SSCC) are 18 digit numbers used to identify logistical units as they move through the supply chain. Learn how to create an SSCC.